Challenge ready technologies

Prefasprzęt supports precast concrete manufacturers in the area of investments concerning the development of production capacities based on the latest available technologies.

The pillars of our business are our partnerships with globally leading suppliers of machinery and equipment and our support for local companies in the field of investment planning and implementation.

Our strengths are our knowledge and experience in the area of the technologies offered, our commitment to the projects implemented and our constant concern to match our offerings as closely as possible to the requirements and needs of the production facility.

Since 2015, we have successfully supported the implementation of more than 70 investment projects.

We look forward to working with you.

Mateusz Florek

President

Technologies offered:

◎ Applied in the production of vibro-pressed small-sized concrete products, production boards in polyurethane coating with LVL plywood core;

◎ Systems for the measurement of the height, weight and surface quality of small-sized vibro-pressed concrete products, together with data collection and management systems;

◎ Systems for controlled and accelerated curing of precast concrete products;

◎ Machines and lines for the production of sewerage (manholes, pipes) and components of energy infrastructure ( spun poles) from concrete;

◎ Lines with tooling for the production of elements used in civil construction: industrial, warehouse and residential;

◎ Automatic cage welding machines and lines for reinforcing cages and meshes.

Sustainability

We provide innovative solutions

We deliver innovative, environmental friendly solutions that achieve high quality and productivity with less time and energy. Waste is reduced. Data management optimizes the need for raw materials and supply chains.

All this contributes to a smaller carbon footprint of production processes.

ASSYX:

- reduction of energy consumption by significantly reducing of vibration time;

- reduction of waste through equal vibration transmission;

- long lifetime - no need for frequent replacement of the boards

- recycling line for ecological treatment of used production boards, extending their lifetime even further

R&W Industrieautomation:

reduction of waste through ongoing monitoring of product parameters;

optimisation of demand for raw materials through analysis of continuously collected data.

Kraft Curing Systems:

cement consumption reduction through humidity control;

unification of curing parameters through distribution of hydration heat;

reduction of waste through uniform curing parameters

Afinitas:

reduced energy input and carbon footprint in the production of concrete sewer infrastructure components compared to plastic solutions;

long lifetime - no need for replacement for at least 100 years.

Vollert:

reduced duration of the constructing process and its handling in terms of material delivery;

reduction of waste and elimination of packaging of building materials;

reduction in transport associated with the delivery of building materials.

partners

projects

We make the selection and implementation of processes simpler

Prefabrication

- we know how!

We have helped to implement more than 70 investment projects since 2015. Our customers appreciate the high-quality of our services and our commitment. The aim of our business is to work effectively with technology suppliers for the benefit of the users of the offered equipment. For both parties of an investment project, we are a partner who takes care of its implementation at the highest level.

We are focused on further development and expansion, with a particular focus on automation, safety and environmentally friendly technologies.

Newsletter

Sign up to receive the latest news.

Keep up to date with the latest technologies.

- Prefabrication in the building industry 29 March 2023

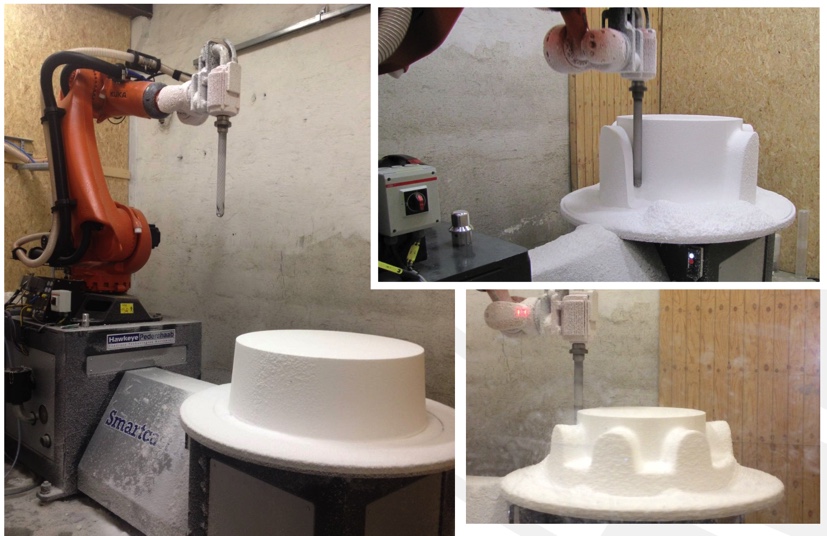

- Smartcast system for monolithic manhole bases 13 January 2023

- Access Anywhere interface – control and remote monitoring of the product curing process 13 January 2023

- KRAFT curing racks – measurable benefits for the prefabrication plant 13 January 2023

- Paving block production boards – an overview of solutions 13 January 2023

- Block height measuring systems – technology for precise production optimisation 13 January 2023

You must be logged in to post a comment.