PRODUCTION PALLETS FOR CONCRETE BLOCK MACHINES

ASSYX PALLETS DUROBOARD - THE NEW STANDARD IN CONCRETE PRODUCT PRODUCTION

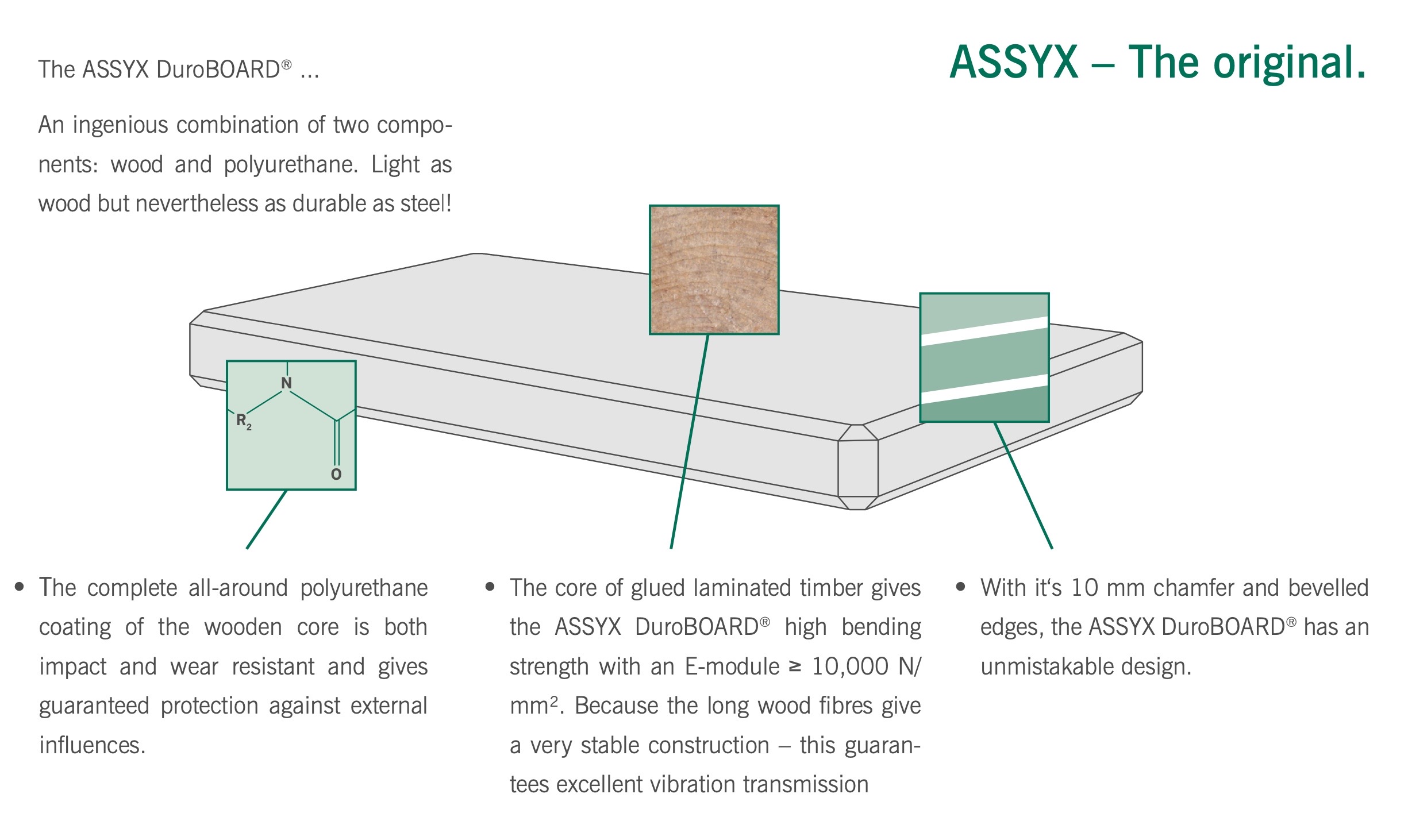

The concept of this innovative solution is based on the combination of a multi-layer glue laminated wooden core with a polyurethane covering, giving a product that is stable, resistant to both static and dynamic loads and abrasion.

THE CORE OF GLUED LAMINATED TIMBER (LVL)

The inner core of the board is a laminated multi-layer timber core (LVL) – https://www.metsagroup.com/metsawood/- manufactured in Finland under the name KERTO-Q by MetsäWood.

Kerto-Q is a construction product approved by Finnish and German building authorities for use in the construction of buildings. The Kerto-Q core is made from European spruce/fir, whereby the trees used are at least 70 years old. It is glued from 15 layers of wood of which the long wood fibres form a very stable structure. This undoubtedly guarantees excellent vibration transmission.

The wood is hermetically sealed in a polyurethane coating and has a moisture content of approximately 7-9% at all times. In addition, 12 of the 15 layers are glued together with a long fibre along the long side of the board, resulting in a bending strength with an E-modul of at least 10,000 N/mm2 (E-modul>10,000 N/mm2 similar to that of hardwood). The bend deflection of the 1400x1100x50mm board is 1.5mm at 500kg load.

In conclusion, the above-described characteristics of the core make it possible to increase productivity by approximately 20 %, as the vibration time is reduced and the number of insufficiently compacted, unmarketable components from the edges of the boards is significantly reduced.

BAYDUR POLYURETHANE COATING

The all-around polyurethan coating of the wooden core of the production pallet is a BAYDUR polyurethan covering with a thickness of 2.5 to 3 mm. The density of the polyurethane is approximately 1,130kg/m3 and its E-modulus is 1,500 N/mm2 .

The Baydur® coating was developed and produced specifically for ASSYX DuroBOARD's by the Bayer Group.

It is both impact and wear resistant and gives guaranteed protection against external and atmospheric influences (temperatures between -25°C and +90°C, ultraviolet radiation).

In addition, it is characterised by its high chemical resistance (all anti-adhesive, anti-stick and other chemicals can be used), does not corrode and has a high durability, as evidenced by the fact that 9 years of use practically does not change the thickness of the board coating (see photos below).

The polyurethane Baydur® is a two-component chemically cured material. It forms a homogeneous protective layer without the addition of any fibres. Thanks to these two characteristics, the board coating is 100% repairable. This makes it possible to keep 100% of the boards in service for their entire life cycle. You can read more about the exceptional lifespan of Assyx worktops HERE.

In addition, the sides of the boards are strenghtened with 300 g/m2 glass matting. The bevelled edges (14x14mm) and the 7mm chamfer on both edges of the ASSYX DuroBOARD are the distinctive feature and guarantee that the boards move smoothly through the entire workflow.

On request, ASSYX pallets DuroBOARD® can be equipped with RFID chips.

BENEFITS FOR THE CLIENT

◎ increased productivity and quality of concrete products in the long term (the use of the DuroBOARD board makes it possible to eliminate the use of protection plates and, through ideal vibration transmission, to produce concrete products of the highest quality;

◎ Consistent height accuracy;

◎ Smooth bottom side of concrete products (which means no additional work and associated costs);

◎ Long durability of DuroBOARD (compared to solid wood and solid plastic worktops);

◎ Relatively low weight of the boards making them easy to handle (DuroBOARD 1400x1100x50mm top weighs about 40 kg),

◎The board, once fully coated with Baydur® polyurethane, will never change its condition, maintains the core moisture content at the initial 7-9% level and continues to transmit a constant vibration over the entire surface for many years (shorter vibration time reduces cycle time and energy costs).

The Assyx Duroboard provides the perfect symbiosis of a dimensionally stable, bend-proof and torsion-resistant core of glued laminated timber and an extremely impact and wear resistant cover of polyurethane. This guarantees an optimal amortisation of your ASSYX DuroBOARD investment!!!

ASSYSX DuroBOARD's are available in popular dimensions: widths 800 - 1800 mm, lengths 500 - 1400 mm, thicknesses 30 - 60 mm.

You must be logged in to post a comment.