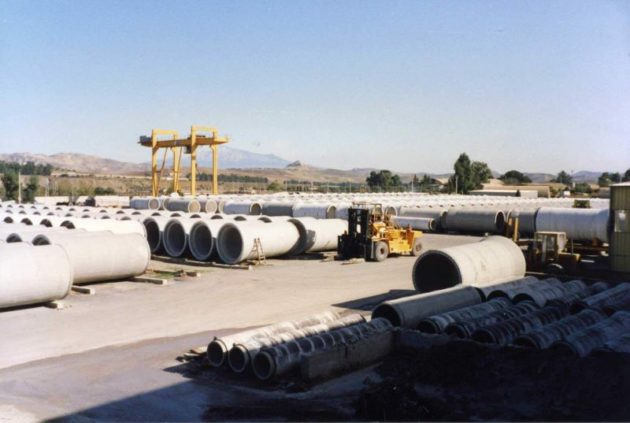

INSTALLATIONS FOR PCCP AND PCSP PIPES (prestressed concrete pipes).

BFS has been designing and manufacturing high pressure concrete pipe equipment for more than 50 years. BFS technology has had a significant impact on the development of pressure pipe manufacturing installations used around the world today. BFS engineers are well equipped to plan and execute complete turnkey plants - from feasibility studies to plant commissioning.

BFS lines meet European (EN) requirements set for pipe plants, American Water Works Association (AWWA) requirements and the requirements of most other rigorous quality standards. With BFS' experience, it is possible to confidently produce prestressed cylindrical pipes (PCCP) or prestressed concrete spun pipes (PCSP).

From the beginning of the cooperation, BFS supports customers in selecting the right system according to their specific requirements. For that purpose, BFS prepares a preliminary plant design with technical and financial details. Once the selection of the system is approved, BFS will manufacture it according to the customer's exact specifications.

The BFS-customer cooperation lasts from the initial discussions up to the professional installation and commissioning of the production line. In addition, BFS technicians are present on site at the start of production to provide training and impart information necessary for the smooth operation of the plant.

Taking advantage of BFS technologies for the production of high-capacity pipes, both Prestressed Concrete Cylinder Pipes (PCCP Pipes) or Prestressed Concrete Spun Pipes ( PCSP Pipes) can be produced.

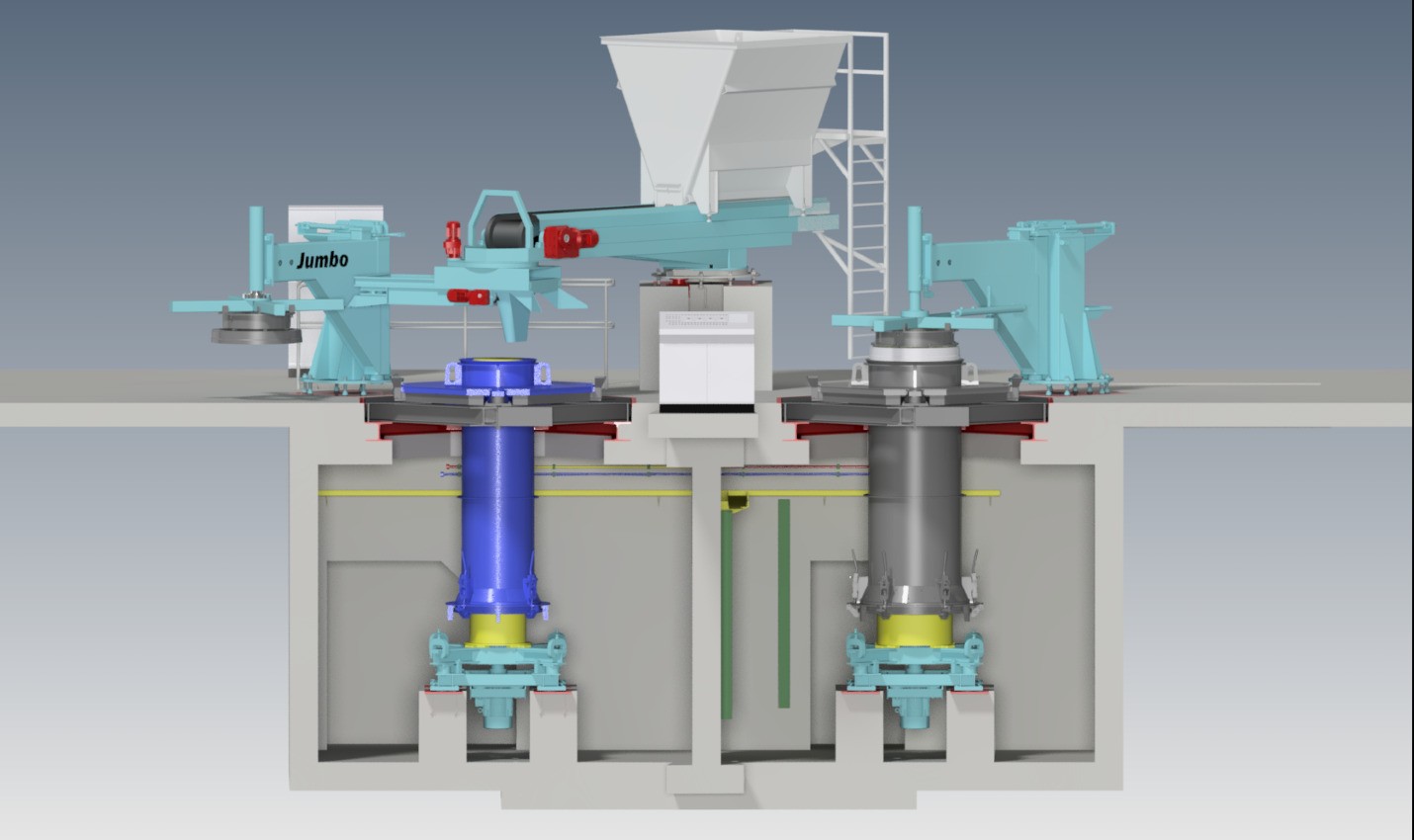

Prestressed Concrete Cylinder Pipes (PCCP Pipes)

PCCP pipes are manufactured in two different ways: PCCP embedded with steel cylinders (ECP) and PCCP with outer steel cylinders (LCP).

For both production methods, BFS offers a complete program for the machine and plant equipment.

In the case of vertical installation, a steel cylinder is embedded in the concrete wall of the pipe. It guarantees tightness even at working pressures above 20 bar (290 psi).

Features of production lines for PCCP pipes:

◎ Special strong and robust design of vertical molds

◎ Easy hydraulic opening of inner and outer molds

◎ Distribution of concrete by motor-driven cone device

◎ Energiczne inner mold with turbo vibrating units

◎ Advanced progressive vibration system along the mold

◎ VAPOR curing in casting molds for approximately 6 hours

◎ BFS circumferential prestressing machine: reliable in maintaining constant pull and pitch of the steel wire along the entire length of the pipe, which guarantees an optimal and uniform resistance to pipeline water pressure

◎ MRC machine to perform an accurate concrete coating of the post compression steel spiral, protecting it from corrosion

BFS MOLDS

Based on more than 50 years of experience in the manufacture of pressure pipe systems, BFS molds have an extremely rigid and robust design, which guarantees a very long lifetime. BFS builds its molds with the same care with which it builds its machines.

Using the strong and robust design of BFS molds will benefit your production in two important ways:

◎ ensuring that geometric dimensions are maintained during vibration

◎ ensuring that geometric dimensions are maintained during long-term operation.

Lower-quality moulds with a flexible design can generate different vibration amplitudes at different mould points, causing inconsistent vibration of the product.

Nominal dimensions of products:

BFS equipment allows the production of PCCP pipes with the following nominal dimensions:

DIN 400 mm to 4000 mm, length up to 8000 mm.

BFS Prestressed Concrete Spun Pipes (PCSP - JACKING)

Produced with BFS Vibro-Press Spinning technology, the pipes are trusted worldwide thanks to their high degree of concrete density.

Features of the production lines for PCSP pipes:

◎ Special strong and solid mold construction for producing jacking pipes

◎ High efficiency of BFS spinning machine: peripheral speed of 30 meters (98ʹ) per second

◎ Hydraulically adjustable wheels to cover a wide range of diameters

◎ BFS vibration system (with separate rings) to compact concrete during mold pouring, especially in the pipe joint areas

◎ Spinning compaction roller that perfectly compacts and creates a smooth inner surface of the pipes

◎ BFS circumferential prestressing machines: reliable in maintaining constant pull and pitch of the steel wire along the entire length of the pipe, which guarantees optimal and uniform resistance to water pressure in the pipeline

◎ MRC machine for performing a thorough concrete coating on the steel prestressing spiral to protect it from corrosion

◎ High performances of the spinning machine (30 meters (98′) per second peripheral speed): hydraulically movable wheels cover a wide range of diameters. The spinning machine’s compacted roller expertly compacts and creates a smooth inner surface.

Nominal dimensions of products:

BFS equipment can produce PCSP pipes with the following nominal dimensions:

DIN 300 mm to 2800 mm, length 5000 mm to 7000 mm.

BFS CASAGRANDE engineers have been initiating groundbreaking changes in the evolution of these production systems for the past 50 years. This has allowed them to achieve the status of technological leaders in this market segment.

You must be logged in to post a comment.