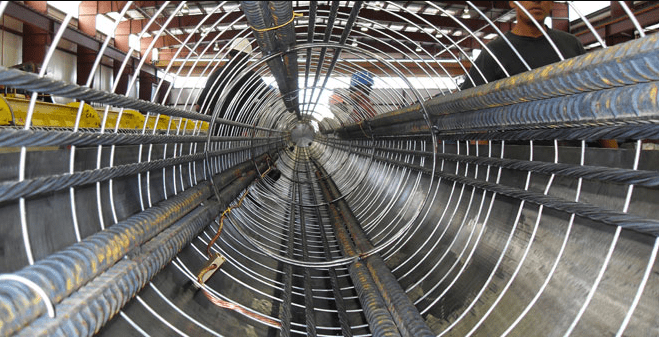

Equipment for the production of prefabricated products using spun concrete technology

Based on the continuously developed technology of spun concrete production, BFS equipment allows the production of prefabricated products from the best class of concrete. The scope of application is:

Masts for:

- power traction

- telecommunication towels

- decorative poles of street lanterns

Piles for:

- foundation of buildings, land and marine structures

- the soil strengthening

- strenghtening of sea shores

Columns for:

- buildings

- ornamental supports with rotationally symmetrical cross-sections

A specially designed production model makes it possible to manufacture pre-stressed concrete or reinforced concrete piles and poles in accordance with site regulations. BFS's extensive range of equipment meets the requirements in terms of production cycles: from the preproduction of reinforcement cages and concrete to prestressing, spinning, curing, de-molding and quality control.

In addition, the use of split molds makes it possible to significantly increase productivity - two products are produced during one production cycle. The degree of automation depends on the customer's needs.

Advanced spun technology includes:

- Bioconical moulds for two pieces or more per mould

- PLC-controlled spinning process

- Quick mold opening and closing procedures

- Quick concrete filling system

- Possibilities for various shaping of conical poles: circular, square, hexagonal, octagonal, fluted, flared, decorative shapes on any regular geometric section

The main features of the spun poles technology:

◎ outer diameter from 300 to 800 mm

◎ length of each element between 6 and 50 m

◎ molds divided into two or more elements

◎ computer-controlled spinning process

◎ faster mold opening and closing process

◎ equipment designed specifically for dry concrete mix: water-cement ratio of 0.3

◎ rapid mold filling system with concrete mix

◎ conical form of piles: circular, square, hexagonal, octagonal, fluted, widened, and as decorative pile if all diameters show regular form.

The main features of the spun piles technology:

Precast concrete spun piles are used, among other things, for soil reinforcement, building foundations and onshore and offshore structures.

◎ diameter from 150 mm to 2000 mm (6″ to 80″)

◎ Length from 6 to 50 m (20′ to 164″)

◎ Pre-stressed or reinforced

◎ Tapered end or cylindrical single piece piles

◎ Jointed cylindrical piles

◎ Square/octogon piles jointed type

◎ Micro piles, H piles

If necessary, columns, piles and pillars can be produced using the vibrating method. For both reinforced concrete and prestressed concrete elements - BFS provides a customized production line.

Poles for power traction - manufacturing

We offer reliable machines for the production of electricity poles using the spinning method. It consists in rotating the moulds in the BFS machines, so that the concrete mixture adheres to their walls and, due to the centrifugal force, is strongly compacted in the tightly closed mould construction. The result is robust spun poles that are resistant to moisture, frost or the effects of high temperatures and can be installed in the ground or underwater.

Spun concrete street lamp poles in various shapes

For concrete prefabrication plants, we offer equipment for the manufacture of spun poles, e.g. for street lamps and the construction or extension of power transmission lines. We offer robust machines that allow the production of poles up to 40 m high in circular, square, hexagonal, octagonal, fluted and also with decorative fragments. With their help, it is possible to equip the pole with a metal box without any problems, as well as to prepare, for example, spun poles with a conical profile, which is often used in the fabrication of lighting poles.

Machines with moulds for the production of concrete spun poles

We offer BFS machines for the manufacture of electricity masts, pillars for building structures or masts for hanging billboards. Our range of products includes split moulds, which significantly increase the efficiency of the plant, as two products can be spun in each process. With their help, every production cycle is carried out with attention to the smallest detail. The equipment allows for almost complete automation of work, which means that the role of employees will be limited mainly to quality control of the produced power poles. We encourage you to familiarise yourself with the details of the offer!

Solid spun concrete poles

BFS is a leader in the creation of advanced production systems for the manufacture of spun masts - concrete poles. We offer both individual machines for semi-automatic operation and complex computer-controlled devices. All moulds are made with attention to detail and are therefore characterised by their tightness. After the spinning process, the precast elements have a smooth surface and are extremely robust. For this reason, every manufacturer of electricity columns or foundation piles should equip themselves with BFS machines.

Please do not hesitate to call us if you have any questions regarding the choice of equipment!

You must be logged in to post a comment.