CIRCULATION SYSTEM FOR MOTUS HOLLOW-CORE SLABS

Hollow core slabs are up to 40% lighter than solid slabs and require less concrete during construction. The hollow core slabs are usually laid unsupported and can be fully loaded immediately. No concreting on site is required.

The use of the circulation system for MOTUS hollow core slab marks a change from traditional and unsupported production. The process of continuous casting on long production beds, the inability to build in reinforcement and cross connectors or other embedded components (e.g. lifting anchors, tension steel or concrete recesses) right away - all this meant that hollow-core slabs were not accepted for building systems in difficult locations (e.g. earthquake zones). In addition, a significant amount of waste was created in the cutting process, which generated costs.

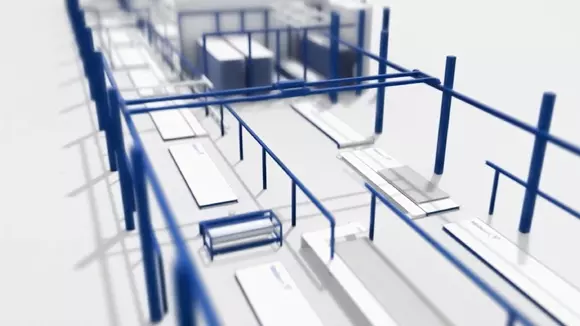

Vollert modernised the production of slabs by offering waste-free production on pallets in a circuit system. The floor slabs are produced according to the exact geometry and dimensions of the building element. Tensioning reinforcements, cross connectors, coupling elements, built-in components and recessed placeholders can be easily installed on the prestressing bed. The fittings for the bumps are only temporarily inserted during the concreting process. The solution from Vollert makes it possible to produce truly earthquake-resistant prestressed hollowcore slabs.

You must be logged in to post a comment.