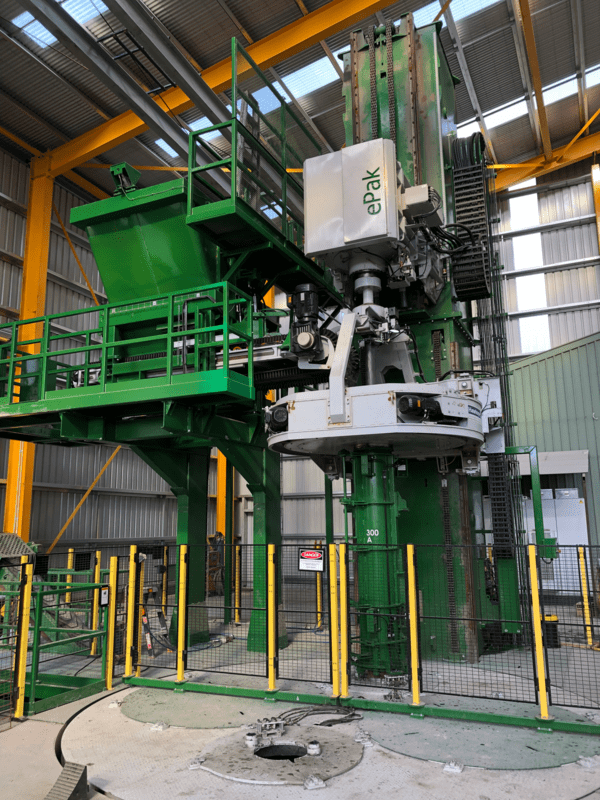

EPAK - HIGH-PRECISION MACHINE FOR THE PRODUCTION OF ROUND THIN WALLED PIPES AND MANHOLE RISERS

Afinitas E-Pak is a revolutionary machine with a rotary packerhead, ideal for high-volume production of round pipes. The EPak produces high-quality pipes with an exceptionally smooth surface; it is ideal for thin-walled pipe production.

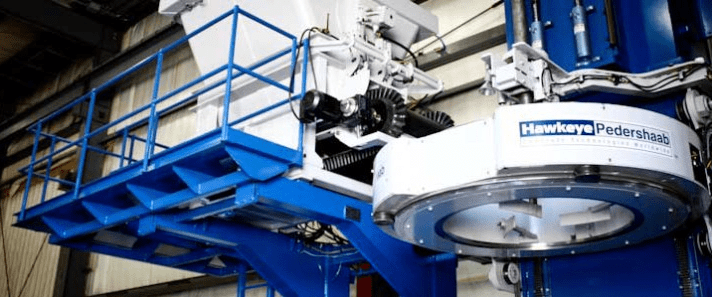

HawkeyePedershaab's EPak machine remains light years ahead of the competition with its surprisingly simple eDrive gearless drive system and precise and reliable control technology.

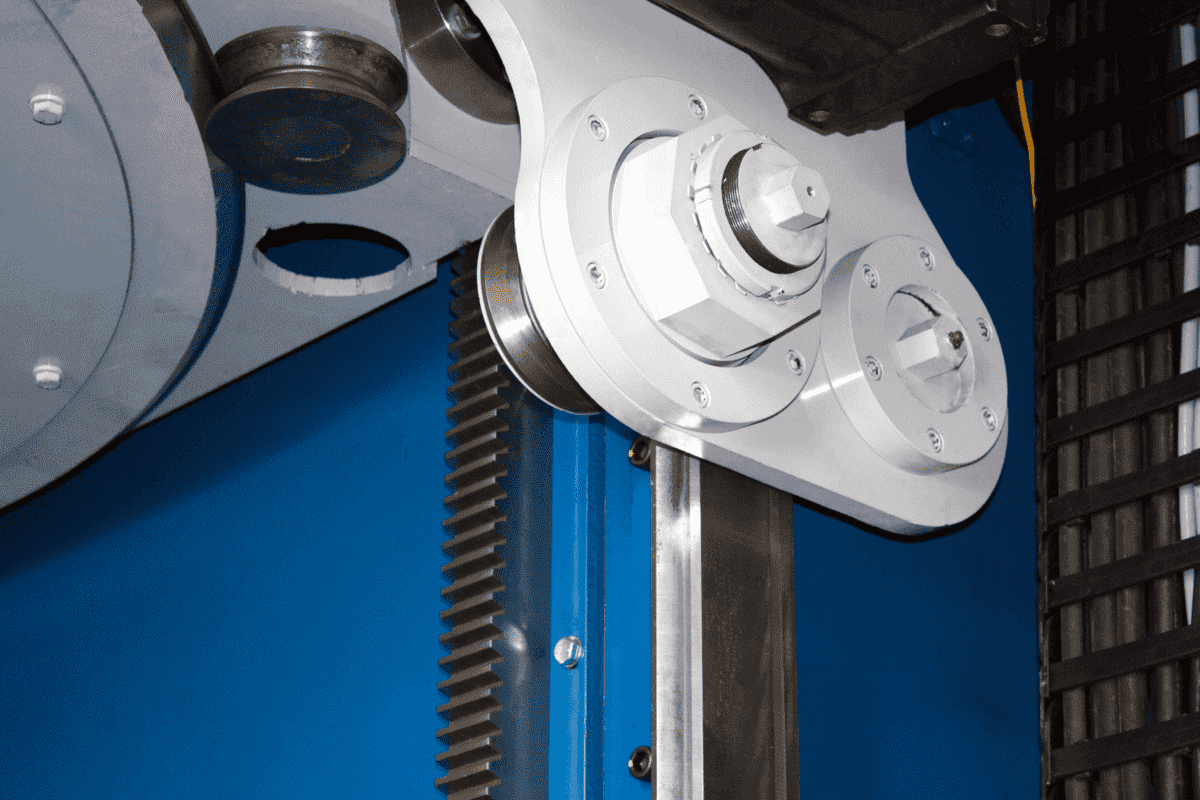

At the heart of the machine is its revolutionary eDrive drive system, driven by a patented gearless 60-pole brushless magnetic motor. With this solution, the eDrive achieves significantly higher torques than conventional drives and additionally has a wider torque/operating speed range - allowing precise compaction control throughout the machine's production range.

Engineered from the ground up, ePak's innovations go beyond the eDrive electronic drive system. Considering mechanical solutions, a unique frame design operating at speeds up to 25% faster than traditional frame designs deserves to be mentioned. In addition, the screwed, two-piece frame design facilitates installation in existing buildings and reduces transportation costs.

The ePak machine is ideally suited for the production of: thin-walled round pipes, precast concrete pipes for the production of manhole risers, vertical rings of sewer manholes, precast concrete pipes, concrete jacking pipes.

Advantages of the system:

◎ Fully automated operation:

which reduces labor costs and enables precise repeatability of production cycles, ensuring that all products are produced with the same high quality.

◎ Precise production control:

Equipped with the most advanced algorithms, the control system and closed-loop control software increase the speed of the production process and maximize pipe quality.

All critical machine processes are constantly monitored, and when necessary, the system makes the necessary micro adjustments. Strategically placed video cameras ensure the quality and maintenance of set product parameters by providing real-time information on the production cycle.

◎ Faster machine operation:

Which is ensured by the unique Uniframe design.

◎ High productivity:

Excellent control technology and fast, smooth component travel speeds result in tremendous productivity.

In a single-shift system, the ePak is capable of producing about 100,000 tons of products annually.

◎ Powerful compaction:

The drive of the packerhead generates more power than conventional drive systems. The wider torque/speed operating spectrum enables precise compaction control over the entire range of pipe diameters. Direct drive from two 60-pole permanent magnet motors does not require gears. This significantly reduces maintenance costs and noise emissions.

◎ Uses existing tooling:

In addition to Hawkeye- Pedershaab tooling, the ePak works with existing tooling from other manufacturers and brands.

◎ Compact machine turntable:

With the ePak machine's compact, electrically driven turntable, the molds can be mounted close to the center point of the table. This allows for higher rotational speeds. In addition, the electric chain drive eliminates slippage, enabling precise speed increases and decreases as the molds enter the filling and shutdown positions.

◎ Fast and smooth travel speeds:

The main drive, top table and trash can are mounted on brackets so they continuously and smoothly move on the ePak machine's unique main frame. As a result, the shocks and vibrations are reduced, minimizing wear and tear on components.

The ePak machine provides up to 25% faster component travel speeds than conventional machines and significantly fewer problems with machine alignment, frame vibration and the need for expensive wear parts. The ePak machine's unique frame design is a twist-together, two-piece construction for easy transport (can be loaded into containers) and installation. The ePak machine uses a barcode coding system for absolute positioning of the crosshead, top table and feeder.

◎ Performance:

All ePak tube production processes are computer-controlled and fully automated. In addition, the finished product and mold can be transported off the machine, de-molded and returned to the machine in an automated process. The molds can also be removed from the machine using a traditional forklift. The ePak can be installed as a stand-alone machine or integrated into a fully automated line.

Standard features:

Reinforcement cages for concrete pipes:

◎ Sturdy Uniframe machine frame on brackets

◎ Gearless, direct-drive electronic packerhead

◎ Top table with trowel

OPTIONAL FEATURES:

The ePak can be equipped with the following additional features.

◎ Forklift-mounted vision controller

◎ Automatic pallet/reinforcement cages feeder

◎ Pallet oiler

◎ Automated feeder for spigot end forming rings

◎ Centering of reinforcement

The ePak machine represents a major step forward in the technology of producing machines with rotary packerheads.

You must be logged in to post a comment.