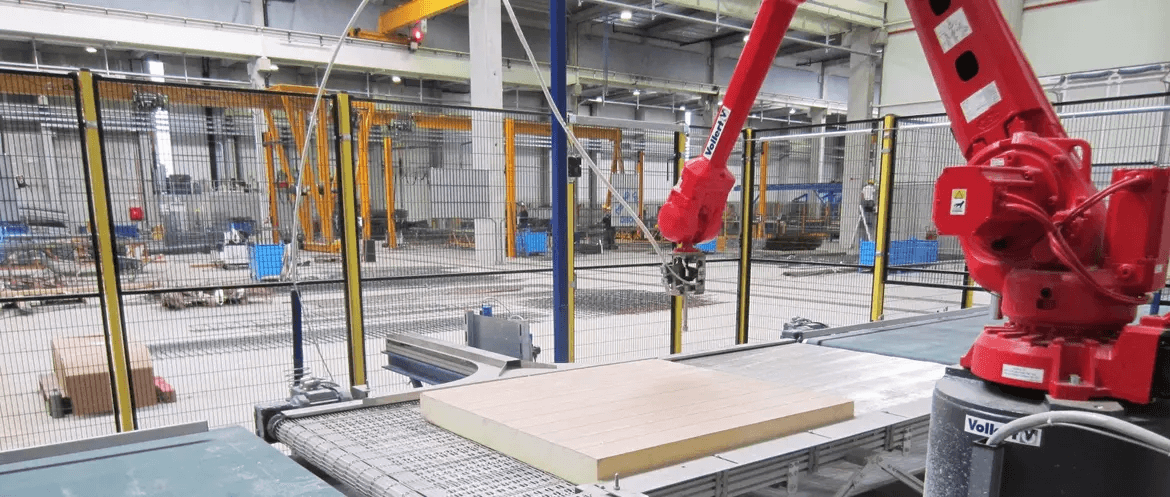

ISO-MATIC WORK STATION

Energy-efficient precast concrete products, such as insulated double or sandwich walls, are increasingly in demand worldwide. This situation is therefore reflected in the need for modern technologies to ensure cost-effective production, enabling high-quality precast components to be manufactured in large output quantities, even in tightly organised processes and short timeframes.

The ISO-MATIC 2.0 workstation saves time and reduces material rejections thanks to the precise and automated cutting of insulation material into any geometric shape (hole circles, diagonals, shafts, etc.).

The dimensions required for cutting are read from the available CAD data. The ISO-MATIC uses this information to make the required cuts fully automatically. Customer-specific basic settings (actual thickness of the insulation board, distance and type of connecting anchors, etc.) can be read out and integrated easily.

Cutting is performed by a precision cutting head with water jet. 4,000 bar ensures that the desired 2D or 3D shape is achieved.

You must be logged in to post a comment.