PDM: Production Data Management System

Production Data Management System

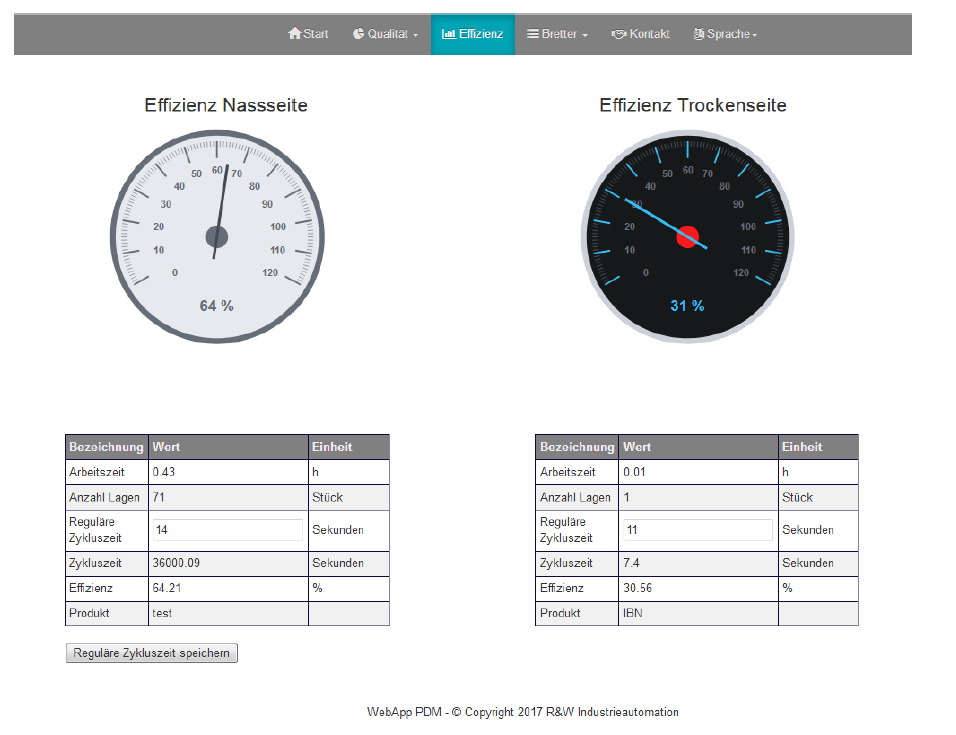

Supporting intelligent production by capturing, storing and evaluating production data

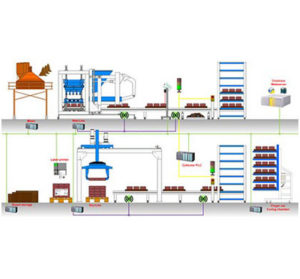

Components of the PDM system PAVE-IT from R&W

In order to be able to record and analyse production data from different systems, it is necessary to use components that communicate with each other. R&W uses the commonly used industrial Ethernet network for this purpose.

How is data management carried out in the concrete plant using the PDM system?

The PDM system records the production data. In order to ensure a closed flow of information from the wet to the dry side, there is a RFID chip technology used to identify the boards.

The RFID chips enable the plate to be identified without any doubt along the entire production path.

The PLC collects quality-relevant data from the mixer controllers, wet side, dry side, quality measuring devices, etc.

Using the chip number, it is possible to assign the information from the database to the corresponding production boards. This makes it possible to assign to each board - and thus to the layer of products produced on it - a great deal of information, such as production data, quality characteristics, etc.

The combination with the Height Control System from R&W allows consistent quality management, as all data for each product layer can be accessed and traced at any time up to the packaging stage.

Quality fluctuations are displayed immediately on the dry side and can be used there for automatic sorting. Similarly, cycle numbers and service intervals of the boards can be documented.

The use of height measurement systems from R&W and the PAVE-IT system can significantly reduce complaints.

PDM od R&W – dla lepszej wydajności produkcji

Inteligentnie skorelowane dane produkcyjne i ich oceny są udostępniane użytkownikom w całym

przedsiębiorstwie za pośrednictwem serwera WEB na bieżąco i w obiektywny sposób.

System zarządzania danymi PDM dostarcza aktualnych i wiarygodnych danych ze wszystkich obszarów produkcji. Ich analiza umożliwia podjęcie właściwych decyzji na poziomie zarządzania firmą.

You must be logged in to post a comment.