STAIR MOULDS

Precast concrete stairs are now an essential component of state-of-the-art residential and industrial constructions. This solution offers many advantages: construction time is significantly reduced, the consistently high quality of the exposed concrete is guaranteed and, in addition, final assembly is greatly simplified.

VARIOSTEP – KOMBISTEP – MEGASTEP - MATRIXSTE

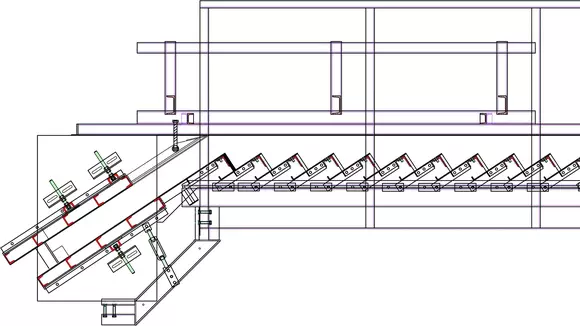

In the VARIOSTEP mould, the staircase is produced on the frame side, which guarantees a 3-sided exposed concrete quality. The additional landing plate is moved horizontally and, thanks to the adjustable height of the back wall, virtually any staircase can be cast using this mould.

With the KOMBISTEP stairmould the stairs are produced overhead. This solution is used in the case of exposed concrete staircases, stairs with edge protection or anti-slip steps or when subsequent sandblasting or grinding is required.

To ensure easy shaping and removal, the mould can additionally be tilted hydraulically.

As a stair variant the QUICKSTEP stair mould provides an electrical adjustment of the staircase design from riser/going.

MEGASTEP stair moulds are used for very wide stairs up to 3 m. The underside is made of exposed concrete with a steel covering, and an optional wood covering is also possible. Mechanical parameter adjustment is carried out manually or via an integrated electric drive.

MATRIXSTEP stair moulds work with a fixed configured step setting, in which the step-fromwork can be exchanged for various stair configurations.

Uncomplicated installation of the rest platform

The platform set for the resting/entry step can be can be attached at any point on the mould.

Optionally, two sets of stairs can be produced with the addition of a platform at the same time, either clockwise or counterclockwise. The addition of the platform can also be completed on any of the steps.

You must be logged in to post a comment.