VAPOR CURING® - controlled heat and humidity supply for better and faster curing

KRAFT CURING's VAPOR accelerated curing systems speed up the hardening process of prestressed elements and precast products.

By emitting heat directly from the combustion chamber, the vapor generator, in combination with temperature sensors and electrically controlled valves, increases the strength gain of concrete and has a positive effect on the its quality thanks to a controlled increase in temperature and humidity. Compared to a steam boiler, the use of the Vapor system results in energy savings of up to 60% and prevents shrinkage scratches.

Depending on its application, the Vapor generator can be configured to meet the needs of various precast concrete industries - Kraft Vapor systems can be used for the production of concrete blocks and wet-cast products, for concrete pipes, drainage elements, precast concrete elements, and for prestressed concrete elements.

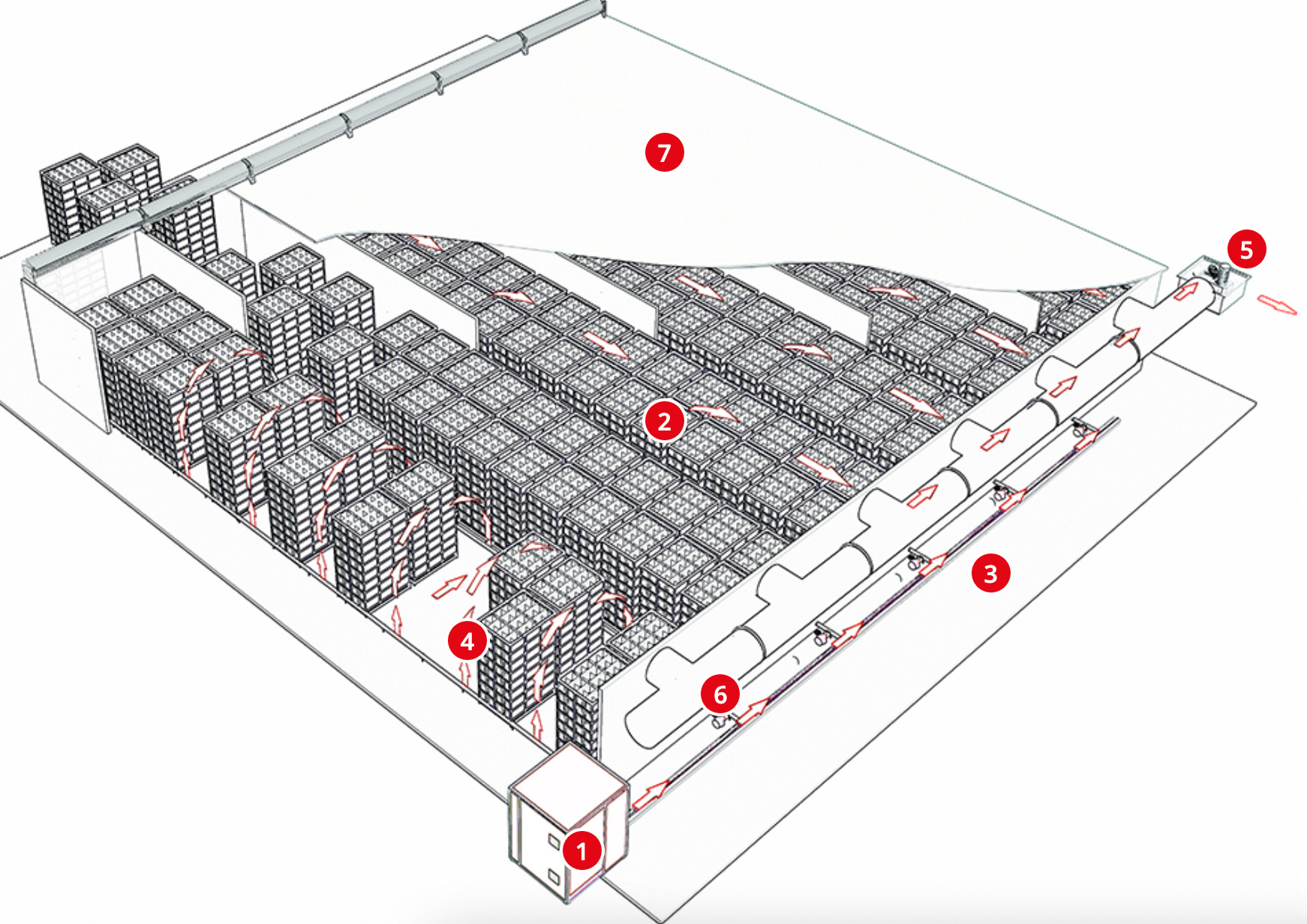

VAPOR CURING I:

FOR CONCRETE BLOCKS AND OTHER CONCRETE PRODUCTS WITH A TREATED SURFACE

The controlled supply of heat and humidity is achieved by using a vapor generator extracting heat directly from the combustion chamber in combination with temperature sensors and motor-driven vapour control valves. By using the VAPOR 1 system, the strength and quality of the concrete are enhanced.

Vapour generator - savings of 40 - 60% in operating costs compared with steam boilers

AutoCure controller - temperature level measurement and control

Stainless steel vapour control valves - in conjunction with the AutoCure controller allows for automated running of the curing process

Uniform vapour distribution (at constant humidity and temperature) through carbon steel and stainless steel pipes of varying diameters

NAUTILUS™ exhaust system for the extraction of steam from one or more curing chambers

NAUTILUS™ radial circulation ventilator

Specially designed insulated curing chambers are equipped with sandwich panels, galvanised steel construction and door frames

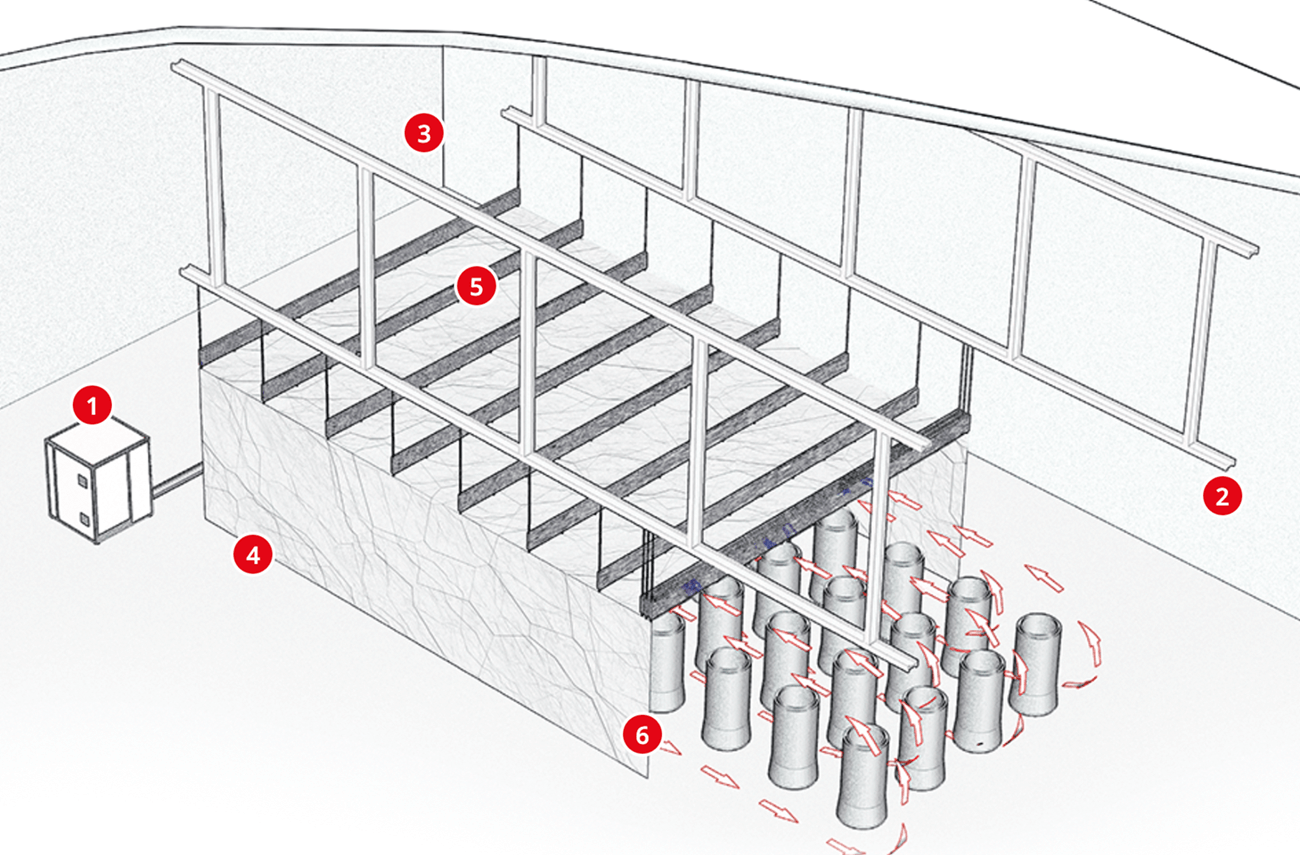

VAPOR CURING II:

FOR PIPES AND PRECAST CONCRETE ELEMENTS

The controlled supply of heat and humidity is achieved by using a vapor generator which obtains its heat directly from the combustion chamber in combination with temperature sensors and motor-driven steam control valves. VAPOR generators can have different capacities and specifications and can be fueled with natural or propane gas.

Vapor generator (saving 40 - 60 % of operating costs compared to steam boilers)

AutoCure controller (temperature measurement and control)

Temperature and humidity sensors (available in wireless or quick-connect versions)

AutoCure controller in combination with stainless steel steam control valve for fully automated operation

Carbon steel and/or stainless steel vapour distribution system - made according to the project

Air circulation ventilator - distributes air and humidity in an even way

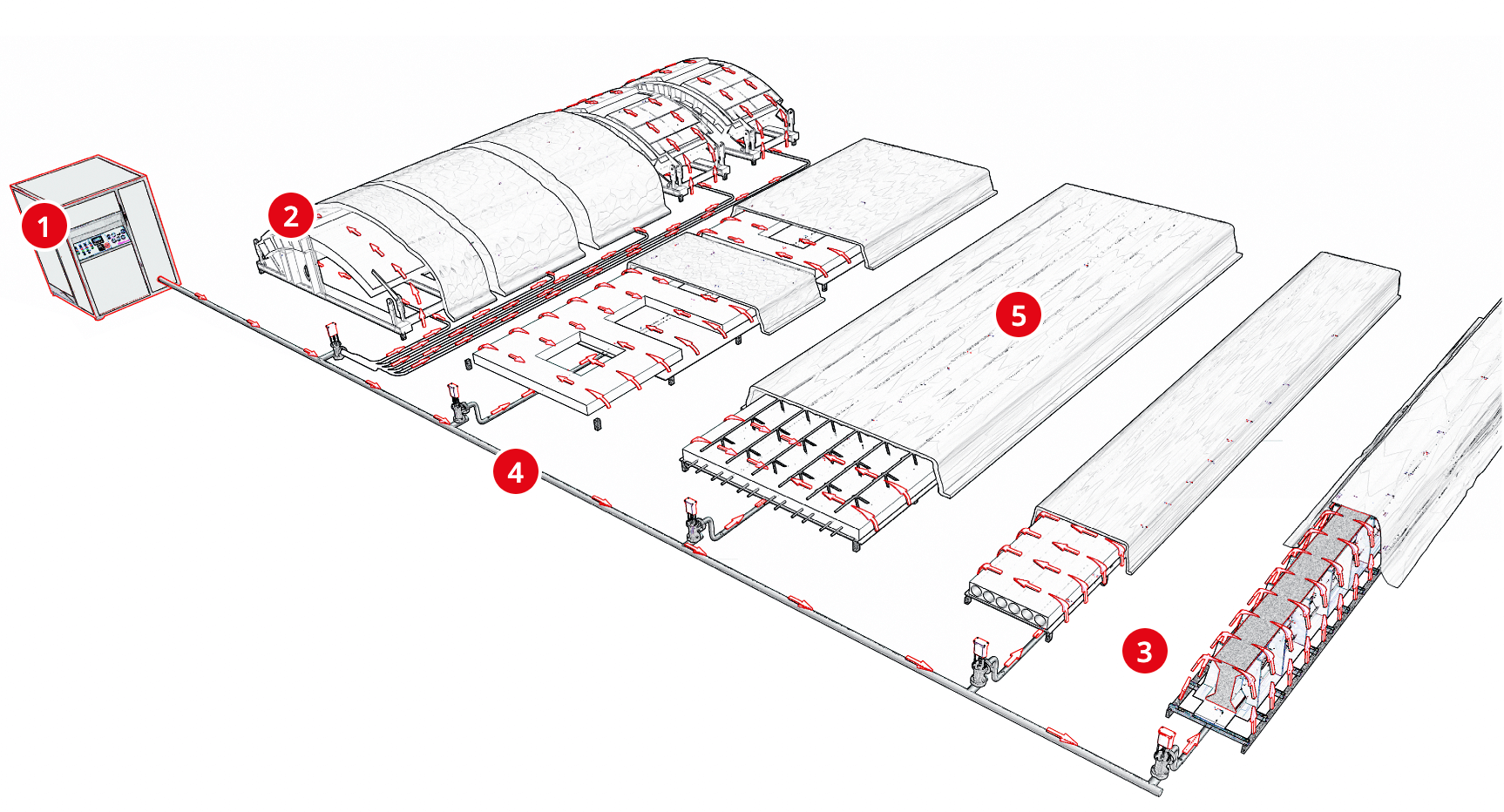

VAPOR CURING III:

FOR PRESTRESSED CONCRETE AND PRECAST CONCRETE ELEMENTS

The controlled supply of heat and humidity is achieved by using a vapor generator obtaining heat directly from the combustion chamber in combination with temperature sensors and motor-driven steam control valves. VAPOR steam generators can have different capacities and specifications and can be operated with natural or propane gas.

Vapor generator (saving 40 - 60 % of operating costs compared to steam boilers)

AutoCure controller (temperature measurement and control)

The AutoCure controller in combination with a stainless steel steam control valve ensures fully automatic operation

Consistent steam distribution (at constant humidity and constant temperature) through carbon steel and stainless steel pipes of varying diameters

Wireless temperature measurement and data recording system.

You must be logged in to post a comment.