VIHY MULTICAST - SYSTEM FOR ALL TYPES OF PRECAST CONCRETE PRODUCTS

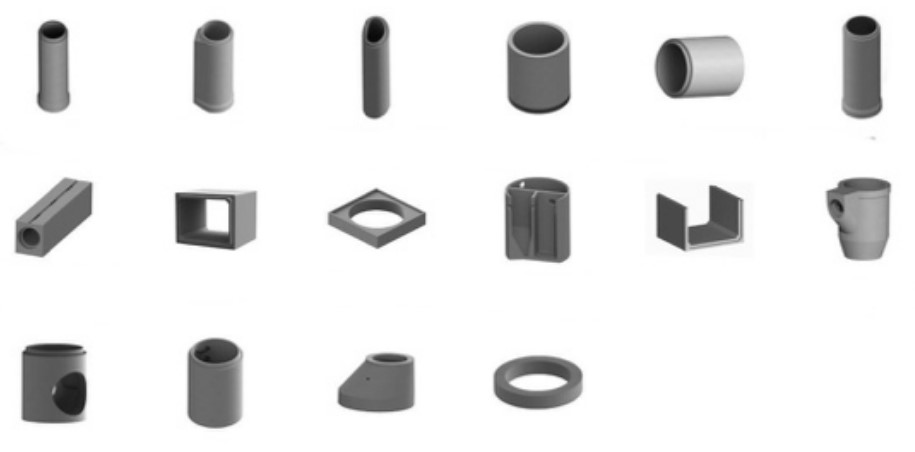

VIHY Multicast - multifunctional system for the production of box culverts, rings and pipes - is an obvious choice where flexibility in production is a must.

The system includes a comprehensive range of production stations: forming stations and vibratory equipment. This makes it possible to configure machinery with a wide variety of production capabilities for making pipes with diameters up to 3600 mm, pipes with an insert, manholes and box culverts with dimensions of 4.0 m x 4.0 m.

The machine's settings can be easily changed to switch production between different dimensions and products - without affecting productivity or quality. Thus, one machine can produce a wide selection of products using mechanized processes that are controlled from a central operator console or from separate control systems on the equipment.

What products can be produced on the VIHY® MULTICAST machine?

Output

Depending on the model and configuration of the machine and the type of products being manufactured, the VIHY Multicast can produce up to 55,000 tons of products annually.

Models

VIHY MULTICAST central core vibration machines

| SCC 150 | SCC 200 | SCC 250 | XL SCC 300 | SCC 360 | |

|---|---|---|---|---|---|

| Diameters | Pipes: DN 300 – 1500 Manholes: do DN 2000 | DN 300 – 2000 | DN 300 – 2500 | DN 300 – 3000 | DN 600 – 3600 |

| Lengths | 3000 mm | 3000 mm | 3000 mm | 300 - 3000 mm | 300 - 3000 mm |

VIHY MULTICAST vertical vibration machines

| SCV 120 | SCV 150 | SCV 200 | SCV 250 | SCV 300 | BC 300 | BC 360 | |

|---|---|---|---|---|---|---|---|

| Diameters | DN 300 – 1200 | DN 300 – 1500 | DN 300 – 2000 | Pipes: DN 600 - 2500 culverts 1800 x 1800 | Pipes: DN 600 - 3000 culverts 2500 x 2500 | Pipes: DN 600 - 3000 culverts 2500 x 2500 | Pipes: DN 600 - 3000 culverts 2500 x 2500 |

| Lengths | up to 2000 mm | up to 2000 mm | up to 2000 mm | up to 2500 mm | up to 2500 mm | up to 2500 mm | up to 2500 mm |

A variety of machine configurations

The Multicast machine series includes a wide range of production stations, concrete feeders and vibrating systems that allow producers to configure equipment to meet their specific requirements. This flexibility provides a cost-effective way to start or expand a plant.

The Multicast can be equipped with manual, semi-automatic or fully automatic control. In addition, the machine can be supplied with a wide range of handling solutions to ensure an efficient production flow.

Multicast machines are available in a single- or dual-station arrangement. Each station can be configured independently in terms of size and/or vibration system. This enables the production of virtually any type of pipe, box culvert or manhole product.

Compared to a single-station machine, two stations give higher productivity, greater versatility and more production flexibility. Investment in a dual station can be made in stages to keep the initial investment threshold low.

Ideal for Lined and Jacking Pipes

The Multicast is particularly well suited for special applications such as lined and jacking pipes. The machine can be supplied in a special 3m version, which is the preferred length for jacking pipes.

In addition, the Multicast can be equipped with a pneumatic system for producing concrete pipes with HDPE, PVC and GRP liners.

All these features enable concrete producers to offer a wide variety of infrastructure products with a single production line.

Unique box culvert solutions

VIHY Multicast - multifunctional system for the production of box culverts - can be equipped with various vibration systems tailored to the production of box culverts. There are vibrating tables that can accommodate box culverts, as well as synchronized core and jacket vibration systems.

Fixed and modular molds are available. Modular molds and joint ring components can be configured to produce box culverts of many different sizes with a single set of components.

Customer benefits:

◎ SCC Core Vibrator:

the precision manufacturing and oil lubricated construction of the vibrator allow it to achieve speeds and power unmatched by competitive vibrators. The use of the core vibrator enables maximum compaction power, reducing cement consumption and maximizing concrete compaction

◎ SCV vibrator (synchronized vibration):

efficient, built-in electrically driven core vibration system allows production of high quality products and speeds up mold replacement.

SCV vibrators can be designed for any type of core, eliminating the need to switch vibrators from core to core during changeovers.

◎ VIHY Vibrating Table:

allows optimum production of a wide range of hard-to-compact shapes that are difficult to manufacture using the traditional core vibration process. These shapes include a range of flat, square and irregular products. The vibrating table greatly expands Multicast's production flexibility.

◎ Laser-controlled X-Y automatic concrete feeders:

computer-controlled concrete feeders X-Y automatically track the perimeter of non-circular products, such as box culverts or elliptical pipes, enabling automatically controlled batching. X-Y feeders are also used to feed the concrete mix to machines equipped with a second production station.

◎ Semi-automatic operation with laser filling monitoring:

to enable automatic feeding of the mix, the Multicast feeder can be equipped with a laser for continuous monitoring of the mold filling level. Mix feeding automatically stops when the mix is filled.

◎ Rotating platform system for the operator:

the molds are surrounded by an operator platform at floor level. These platforms allow direct and safe access to the molds during production, as well as hookup and unhookup of products using a crane.

◎ Optional:

- press head system

- quick mold changing system

- double set of external molds for increased production

- cast-in-place manhole steps

- anchor automation.

You must be logged in to post a comment.