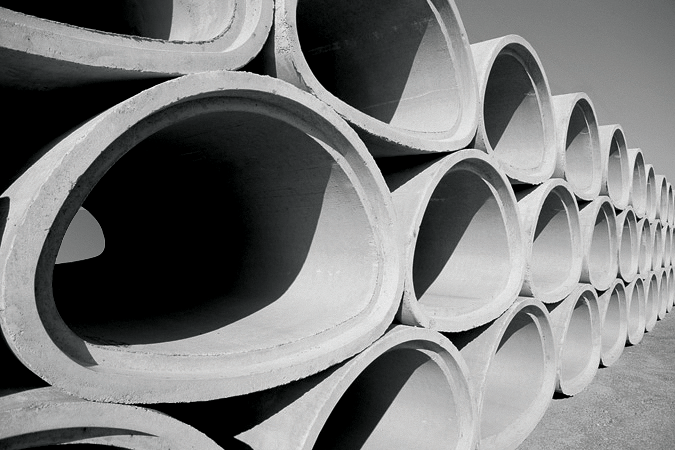

VIHY PIPEPRO - AN EFFICIENT MACHINE FOR THE PRODUCTION OF CONCRETE PIPES OF VARIOUS CROSS-SECTIONS

VIHY PIPEPRO - the machine for the production of concrete pipes of various diameters and coils provides the perfect solution for manufacturers of sewer and manhole components. The system allows the simultaneous production of products of different dimensions in mass quantities (in fully automatic or semi-automatic set-up).

The perfect combination of automation, performance and versatility - three seemingly competing features - is integrated in the PipePro into one unique package. A single PipePro machine can produce most common products: elliptical, arch pipes and jacking pipes as well as manhole components.

Equipped with Multiform modules, PipePro can produce up to four or eight different pipes (depending on the machine model). PipePro guarantees versatility and performance incomparable to any other machine.

What products can be produced on the PIPEPRO machine?

Output:

Depending on the machine model, a typical PipePro machine offers an annual production capacity of 70,000-80,000 tons of product with single-shift operation.

Models:

HawkeyePedershaab PipePro XT

HawkeyePedershaab PipePro 96

| HawkeyePedershaab PipePro | PipePro XT | PipePro 96 |

|---|---|---|

| product dimensions | diameter 300-1800mm | diameter 300-2400mm |

| product length | to 3.5M | to 3.5M |

| Max. number of multiform | ||

| Singleform | diameter to 72" | diameter to 96" |

| Duoform | diameter to 30" | diameter to 48" |

| Triform | diameter to 24" | diameter to 39" |

| Quadform | diameter to 18" | diameter to 30" |

| SixPak | diameter to 24" | |

| EightPak | diameter to 18" | |

The main benefits of using the machine are::

◎ Fully automatic operation:

In PipePro, the PLC's advanced hardware and software algorithms professionally manage the production cycle. Operation begins with a simple screen menu that easily allows you to enter machine settings and product dimensions.

From then on, the PipePro machine takes over: the paddle feeder automatically positions itself over the mold in the filling station and begins feeding concrete into the mold set and compacting it using vibration. PipePro's carousel press head picks up and pushes the head into the filled mold set to form the spigot end. The laying, pressing and troweling operations are completely automatic.

The finished concrete pipe can be removed from the machine automatically or manually using an overhead crane. The product is then safely transported to the curing area in the outer mold jacket.

◎ PipePro three-station turntable - three-station capacity:

The three-station design of the PipePro turntable shortens the steps of filling, pressing and removing products from the machine, speeding up the production cycle and increasing productivity.

In addition, the PipePro allows the simultaneous production of three different sizes or shapes of concrete pipes. This means that with PipePro, any combination of circular, arch and elliptical pipes can be produced, as well as jacking pipes and manholes.

◎ PipePro multiforms - boosting productivity:

HawkeyePedershaab's patented multiform modules are used to further increase productivity. Up to eight pipes can be produced in a single molding module. Depending on the machine model and product diameter, PipePro can produce up to 100 pipes per hour.

◎ PipePro's fast mold changeover:

Simple, quick-disconnect attachments and modular molding elements eliminate the need for time-consuming adjustment and set-up of molds to the machine. With the PipePro system, molds can be changed in as little as thirty minutes.

◎ PipePro's spigot end - consistent, repeatable results:

The PipePro system's computer-controlled feed rates and vibration settings are specific to each type of concrete, ensuring high quality. In addition, the PipePro compaction system uses press heads that stay in place, ensuring smooth, dimensionally accurate spigot ends every time.

Standard features

- Three-station turntable with built-in operator platform

- Automatic system of compaction heads

- Automatic concrete feeding system

- Components for rapid mold changeover

- PLC control system with touch screen interface

Optional features

PipePro can be equipped with the following additional features:

- Variable vibration frequency control

- Automatic lifter

- Automatic pallet/reinforcement cages feeder

- Remote lubrication kit

- Feeder load sensors for automatic dispensing

You must be logged in to post a comment.