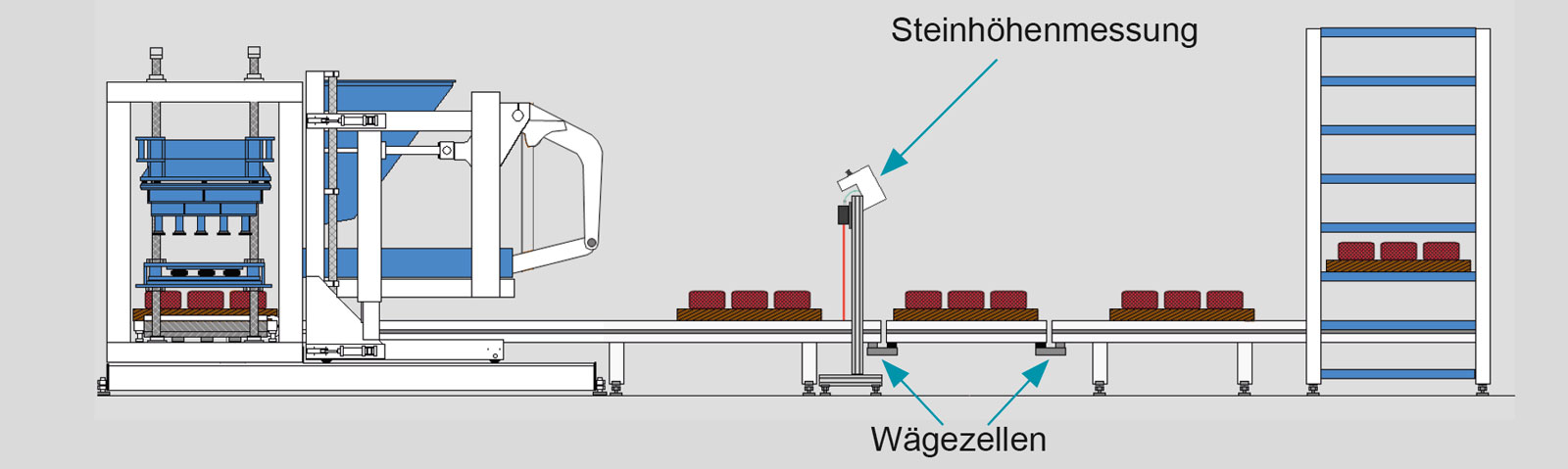

The weight control of products - the precast weighing system

In addition to height, an important quality characteristic of freshly manufactured concrete blocks is their weight.

The system for weighing cube tops is installed directly behind the Height Control System. A conveyor drops the board on a weighing tensor rack. The tare weight of an individual board can be indicated in the SHV-VISU software or read from an RFID chip mounted in the board.

The weighing system measures the weight of the entire load and calculates the weight of the concrete based on the difference between full and empty weight. The measurement result is then transferred to a PC running the SHV-Visu software, where it is displayed and stored.

The control of the weighting unit is based on a Simatic S7-1200 processor and communicates with the machine controller (signal exchange for mutual release), as well as with the laser sensors for measuring the height of the products and a PC with SHV-Visu software.

The weighing electronics are installed in the SHV500 control box. The load connection boxes are mounted as close as possible to the weights.

FUNCTIONS OF THE WEIGHT CONTROL & MEASUREMENT SYSTEM

◎ measurement & control of the weight of blocks

◎ electronics for weight measurement

◎ weights and accessories for the weight-measuring electronics

◎ SHV-Visu software extended with tabletop weight measurement panel

◎ accuracy class C3

◎ 3 m connecting cable, 4 wires

◎ base plate and elastomer bearing; material: stainless steel, protection class: IP68

◎ nominal load: 500 kg

You must be logged in to post a comment.