VIHY KASTMASTER - ULTRA-FAST MACHINE FOR THE PRODUCTION OF PIPES AND RINGS

VIHY Kastmaster is an automated vibratory press for ultra-fast production of a full range of high quality manhole products and pipes. Its simple, practical design enables its installation both as an independent machine or as part of a fully automated system.

Designed as a stand-alone machine (or as part of a larger production line), the Kastmaster enables the production of concrete pipe and a wide range of manhole products with only one or two operators.

The machine's robust four-column frame, possible two different types of vibration, and the ability to use rotators to form profiles allows efficient production of a wide range of standard and specialty products.

The machine's automated production cycle and advanced computer-controlled operating system are a guarantee of high-end products.

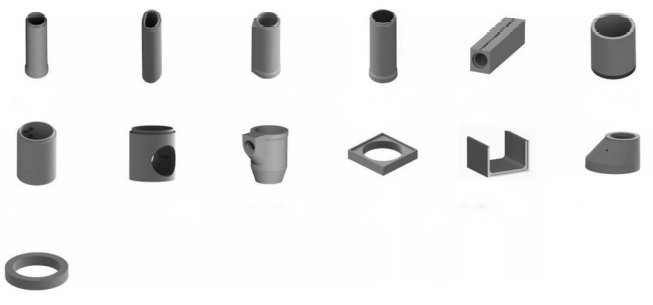

What products can be produced on the Kastmaster machine:

Output:

The Kastmaster offers an annual production capacity of 50,000-60,000 tons of product in single-shift operation. The machine's design allows it to accommodate multiple modules for increased capacity.

Models:

Kastmaster 150/200 (product dimensions: diameter: 300 to 1500 mm; length: 0.25 to 2 m)

Kastmaster 150/250 (product dimensions: diameter: 300 to 1500 mm; length: 0.25 to 2.5 m)

Kastmaster 200/250 (product dimensions: diameter: 300 to 2000 mm; length: 0.25 to 2.5 m)

System benefits:

◎ Fully automatic operation:

Kastmaster automation reduces labor costs and enables precise repeatable production cycles, so that all products have the same high quality. The machine is designed with an infeed shuttle that automatically feeds pallets and reinforcement to the production station as a corresponding outfeed shuttle transports finished products to a pickup position.

◎ Rational - linear - production flow:

Kastmaster dual shuttle carts organize the feeding of pallets and cages into the machine from one side and the unloading of finished products from the other side to the pick-up point. One operator can easily monitor and control the machine from a centrally located console. The machine's design ensures easy access to both shuttle cars to undertake necessary auxiliary operations while the machine is in operation.

◎ Production flexibility:

To maximize production flexibility, the molds are designed as stand-alone modules connected to the machine by hydraulic clamps that allow them to be changed over in just 30 minutes.

In addition, the Kastmaster can be equipped with various vibrating systems, including, for example, a vibrating table for the production of concrete pipes, manholes and slab-type products.

In addition, a mold turning device can be added to the Kastmaster so that products made in rotary molds can be turned 180° before being de-molded.

◎ Production versatility

The Kastmaster can be equipped to manufacture round, oval, arch, and box-shaped concrete products in diameters up to 2000mm x 2.5m lengths – as well as jacking pipe, lined pipe, and the full range of manhole riser, cone, and base products.

◎ De-molding in the machine - no overhead crane required:

Products are produced and disassembled in the machine, saving construction and equipment costs by eliminating the need for a factory crane.

◎ Handling:

The VIHY Kastmaster can be operated by a single operator without extensive training.

The machine has fully automated production, including de-molding and unloading of the finished product. The feeding of pallets and reinforcing steel into the machine is also automated. Finished products can be removed manually using a cart or with automated robotics. The underground casting station provides a safe working environment for the machine operator and a comfortably low noise level.

Machine features:

Standard features:

The VIHY Kastmaster can be equipped with VIHY central core vibration, creating horizontal core vibration and, in addition, vertical vibrators; or a combination depending on customer needs

- Swipe feeding system

- compaction head system

- operator console

- integrated de-molding system

- cart for transporting pallets/reinforcement bars

- cart for transporting finished products

Optional features:

VIHY Kastmaster can be equipped with the following additional features:

- quick mold change elements

- pallet oiling

- automated forming ring feeder unit

- automated forming ring feeder spigot end

- wall-integrated lifting anchors

- centering of the reinforcement

The following additional features are available to enable manhole production:

- manhole module

- vertical vibration for the production of cover plates

- automatic mold rotation module for manhole production

- wall-integrated manhole steps or tiers.

You must be logged in to post a comment.