PRODUCTION CONTROL SYSTEM

THE BRAIN OF THE MODERN PRECAST CONCRETE PLANT

MÓZG NOWOCZESNEJ PREFABRYKACJI BETONOWEJ

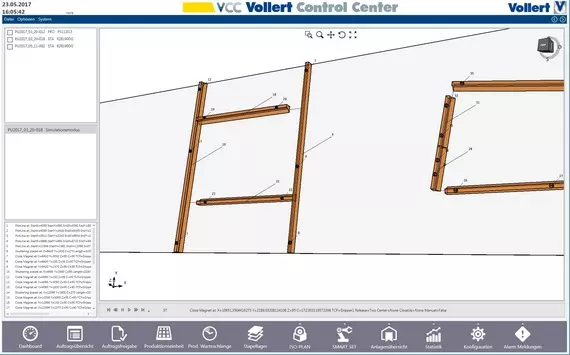

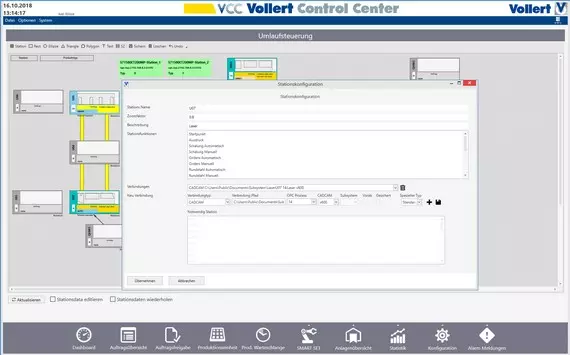

Today, a state-of-the-art production control system ensures an optimal and punctual delivery of the required precast concrete elements to construction sites and customers. It continuously controls and monitors all processes and machines in a precast concrete plant, from work preparation and workstations to storage and loading processes. It is the central interface for constructively created data from the BIM model and existing ERP systems.

Consequently, it is also called the brain of a modern precast concrete plant. The Vollert control centre contains all the typical CAD/CAM interfaces of the industry.

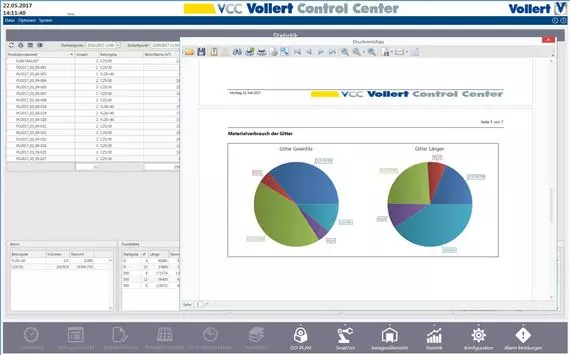

Pallet allocation is optimised, all machines can be controlled and data automatically tracked and processed, picking sequences and curing times are managed and, in addition, numerous statistics are made available.

All important order lists and key figures are always in sight. Printouts of labels, components, allocation plans or their visualization at the workstation facilitate the production process and subsequent storage location management.

Already in the development phase, attention was paid to a simple operating concept - learning by doing.

You must be logged in to post a comment.