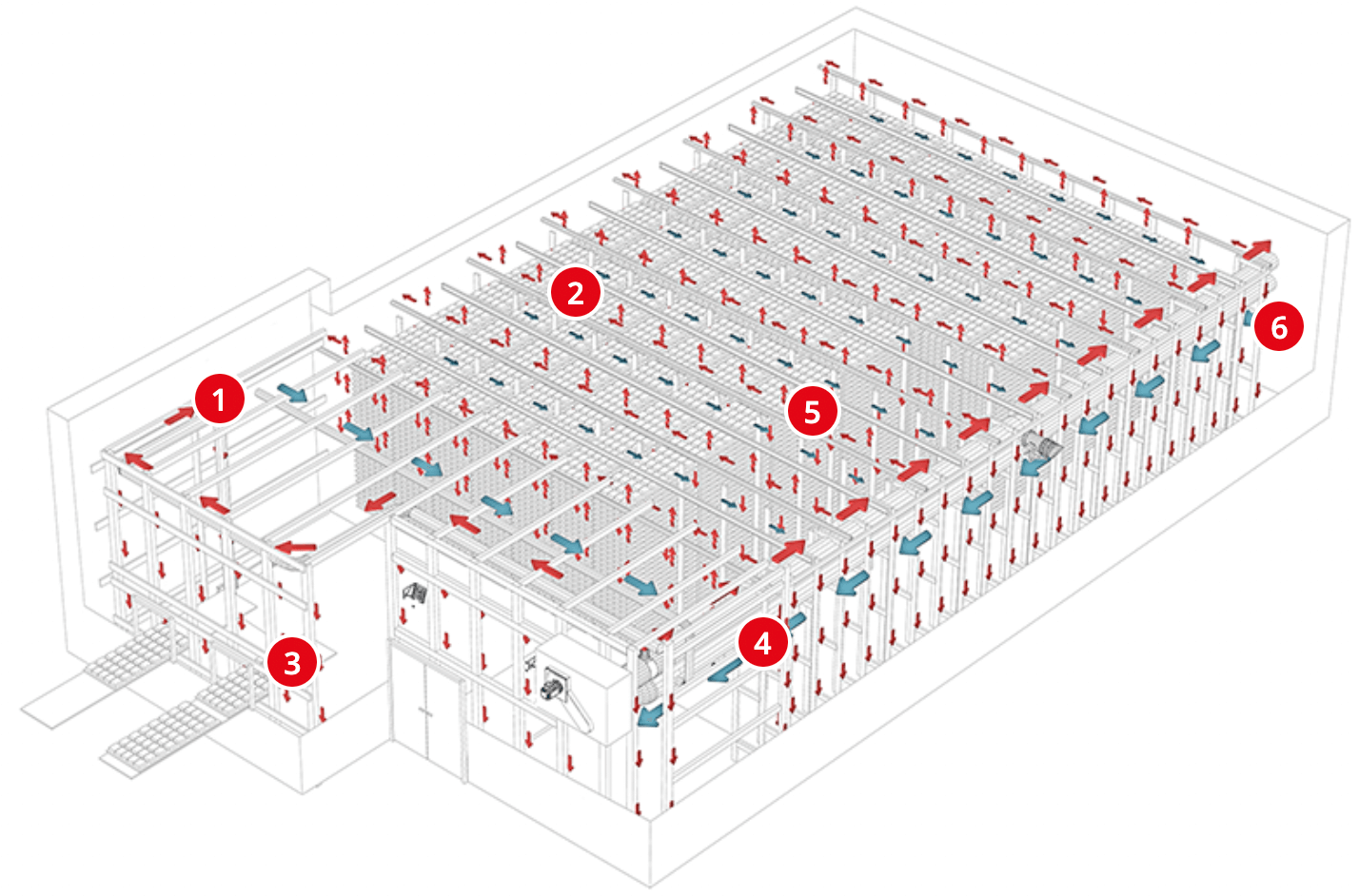

NAUTILUS™ - air circulation system for large chambers

The NAUTILUS™ air circulation system from KRAFT CURING optimizes the cement hydration process by circulating heat from hydration and humidity from fresh concrete to create a uniform curing environment in a large chamber.

Kraft Curing guarantees:

• consistent curing temperature across the entire chamber within +/- 1 °C and relative humidity within +/- 3%

• air flow at a level of ≤ 1 m/s

• humidity level controlled based on curing temperature

Customer benefits::

• reduced hardening duration, less breakage

• consistent colour, significantly less risk of efflorescence

• no condensation on surfaces inside the chamber

• 5% saving on cement year on year

Curing chamber with insulated sandwich panels - reduced energy loss (possible to make the housing yourself according to construction drawing, instructions and parts from Kraft)

Corrosion-resistant steel construction and sensors (photodetectors or laser sensors) to ensure proper temperature and relative humidity levels (no fog or condensation in the chamber)

Radial ventilator made from stainless steel and aluminium (with self-lubricating stainless steel bearing housing) - manufactured specifically for the construction industry

Vertical air ducts for homogeneous heat and humidity distribution; at each level - ventilation dampers for constant and low air flow

AutoCure® controller to regulate, monitor and record air temperature and humidity in the chamber

Electrically driven exhaust system to reduce air humidity

Temperature and humidity measurement - by sensors placed in the chamber

You must be logged in to post a comment.