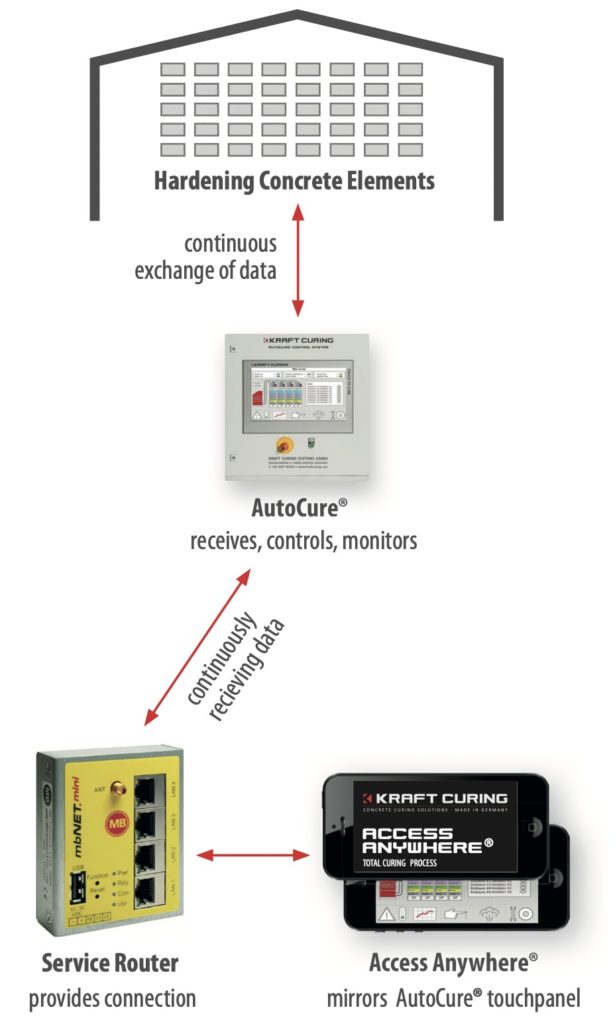

1. Control and monitoring of the product curing process from anywhere

The Access Anywhere interface as part of the AutoCure® system guarantees full access to the curing process of concrete product from any communication device (computer, tablet, phone) and provides a helpful solution for technicians and production managers who need to ensure that processes run smoothly every day (you can read more about AutoCure here).

With the interface, it is possible to remotely observe, monitor and control the curing process of concrete products in the curing chamber. The process of controlling the equipment to achieve the set parameters, thanks to the use of the interface, can take place not only in the production plant from the system screen, but from anywhere on earth, at any time.

Access Anywhere service router

2. Features of the Access Anywhere interface

The interface allows, among other things:

- changing settings in the event of, for example, a change of assortment;

- reading and comparison of process parameters;

- archiving and creating analyses to support the quality control process.

ACCESS ANYWHERE® provides instant mobile access to concrete curing process data, mirroring the interface normally only available on the AutoCure® screen at the factory, as well as access to the PLC and insight into software changes.

If there is an indication of a problem, the plant production manager or a KRAFT CURING technician can remotely check what the problem is.

With pressure sensors instead of pressure gauges, ACCESS ANYWHERE® can show whether the pressure level is too low or too high and whether it needs adjusting.

If there is no network available, or if Kraft service technicians cannot access the AutoCure® PLC via a custom server, the connection can be established over the Internet using a service router.

As a stand-alone product or in combination with ACCESS ANYWHERE®, this add-on allows Kraft service technicians to access the AutoCure® PLC from anywhere in the world.

3. What do you need to use the Access Anywhere interface for remotely monitoring the curing of products?

ACCESS ANYWHERE® includes a licence to access the touch panel to view and change curing system parameters. The software creates a copy of what you see on the touch panel on your laptop, smartphone or tablet.

A local network connection is required for connections within the network and a VPN (service router) connection is required for connections outside the local network.

This item does not include a service router, which is required for remote connections outside the local network (for example, a connection from home to a curing system in a factory).

A comfort panel (not basic) is required.

4. What is needed for full remote access?

For full remote access you will need to use the service router module. This module provides a remote connection between the user and the Siemens PLC. The router module requires the customer to supply the following:

- 24 VDC power supply connection (already available in the control cabinet from Kraft Curing),

- Ethernet connection to the Siemens PLC (either via a switch or directly to the CPU), and

- Ethernet connection to the Internet (fixed IP address or IP address via DHCP server).

Once properly installed and connected, the router allows remote access to the PLC from anywhere in the world via the Internet.

This module allows Kraft technicians to remotely access the system for remote diagnostics and, in certain circumstances, to make changes to the program if required.

The service router does not include a licence for remote viewing of the AutoCure® software, which is displayed on the touch panel.

You must be logged in to post a comment.